CNC Machining Parts Tolerance Guide: Choosing the Right Precision Level

Date:2026-01-31Article editor:Starting Point PrecisionViews:18In CNC machining, tolerance is the permissible limit of variation in a part's dimension. Selecting the right precision level is a critical decision that directly impacts your part's functionality, manufacturing cost, and lead time. This guide will help you navigate the key considerations.

Understanding Tolerance and Standards

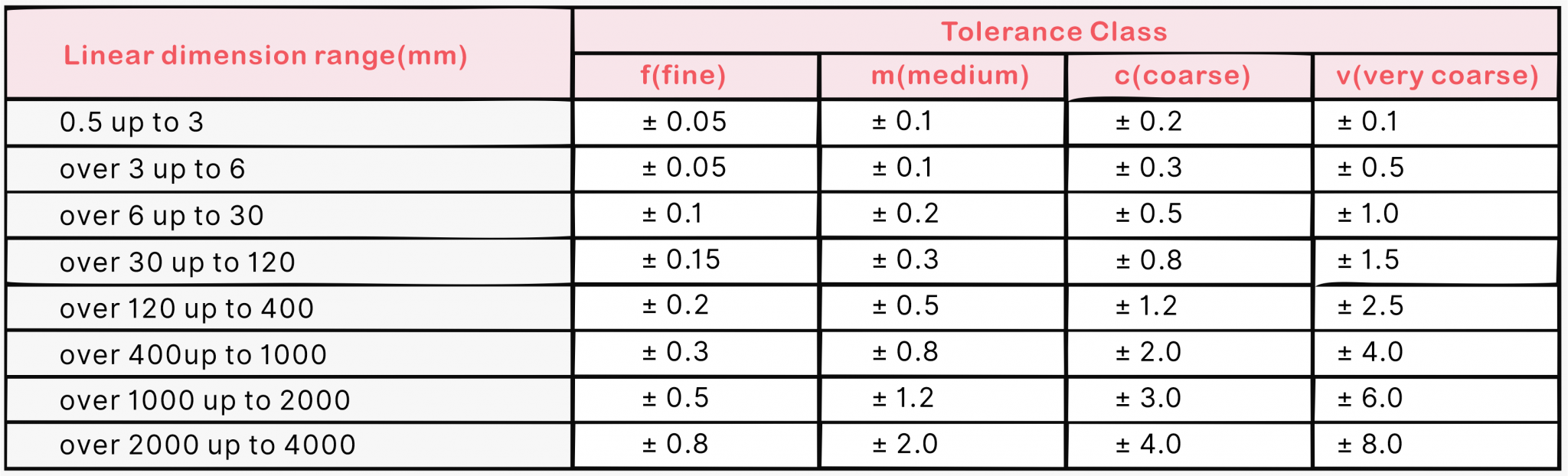

A tolerance is expressed as a deviation (e.g., ±0.1 mm) from a nominal dimension. Tighter tolerances mean higher precision but greater manufacturing complexity. International standards, such as ISO 2768 , provide general guidelines for machining tolerances, offering a common language for designers and machinists.

Common CNC Tolerance Grades

Coarse Tolerances (±0.5 mm or more): Suitable for non-critical features like rough housings, brackets, or prototypes where fit and finish are not paramount. This level offers the fastest and most cost-effective production.

Standard Tolerances (±0.1 mm): The most common choice for many applications. Achievable reliably with standard CNC processes, these tolerances are ideal for parts that require reliable fit and interchangeability without extreme precision. For example, many machined enclosures use this range.

Fine Tolerances (±0.025 to ±0.05 mm): Required for parts in mechanical assemblies, such as gears or bearing fits, where precise alignment is crucial.

Very Fine Tolerances (< ±0.025 mm): Approaching the limits of CNC milling and turning. Essential for aerospace, medical devices, or optical components. Achieving this demands high-end machines, stable environmental conditions, and significant expertise, leading to substantially higher costs.

How to Choose the Right Tolerance Level

Follow this practical approach to specify tolerances wisely:

Define Critical Features: Not every dimension needs to be tight. Identify the critical interfaces, mating surfaces, and functional geometries that truly demand high precision. Apply tight tolerances only there.

Consider Material and Process: Some materials, like aluminum, are easier to hold to tight tolerances than others, like plastics, which can warp or shrink. The machining process also limits achievable precision.

Apply the Cost vs. Benefit Rule: Tolerances tighten exponentially. A part with ±0.025 mm tolerance can cost 2-3 times more than one with ±0.1 mm. Always ask: "Does the function justify the added cost and time?"

Communicate with Your Manufacturer: Early consultation with your CNC machining partner is invaluable. They can advise on manufacturability and suggest adjustments that maintain function while reducing cost. Reviewing a tolerance chart together can clarify expectations.

cnc-tolerance-chart

Best Practices for Tolerance Specification

Use GD&T (Geometric Dimensioning and Tolerancing): For complex parts, GD&T is a superior system that defines not just size, but also form, profile, orientation, and runout, providing a more complete control blueprint.

Avoid "Over-Tolerancing": Defaulting to tight tolerances on every dimension is a common but costly mistake. It increases inspection time, scrap rates, and may require secondary operations like grinding.

Reference Standards Wisely: Notes like "ISO 2768-m" on your drawing set a useful default for all non-critical dimensions, allowing you to only call out tighter tolerances where needed.

Conclusion

Choosing the correct CNC machining tolerance is an exercise in balancing performance, budget, and timeline. By understanding the available precision levels, applying tight tolerances strategically, and collaborating closely with your manufacturing expert, you can ensure your parts are built right—without unnecessary expense. Start your next project with a clear tolerance strategy for optimal results.

Copyright © 2019 All Rights Reserved Dongguan Starting Point Precision Technology Co., Ltd. Tel: +86-769-82855591

Add: No. 332 Zhen'an Middle Road, Chang'an Town, Dongguan, Guangdong, China